- B-465, Industrial Estate 2nd Gate, Karnataka, India

- info@magtoolsindia.com

- Mon - Sat 8:30AM - 20.00

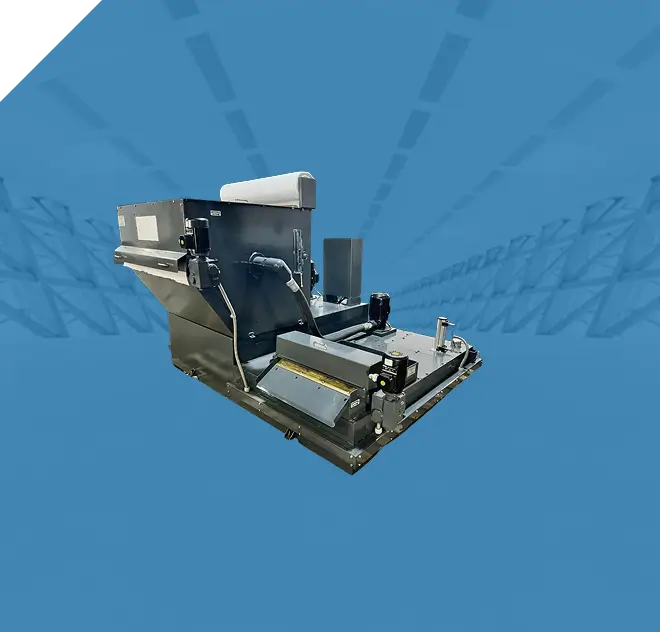

**Mag Tools Coolant Filtration Systems with Chilling Unit**

Mag Tools presents state-of-the-art **Coolant Filtration Systems with Chilling Units**, designed to optimize machining performance by ensuring clean, temperature-controlled coolant circulation.

**Key Features:**

**Benefits:**

Mag Tools coolant filtration systems are widely used in various industries such as metalworking, automotive, aerospace, and manufacturing sectors. These systems are designed to efficiently remove contaminants, debris, and metal particles from coolant fluids, Providing a clean and consistent coolant supply for optimal performance of machining tools and equipment.

Some common applications of Mag Tools coolant filters include:

Overall, Mag Tools coolant filtration systems play a critical role in enhancing the reliability, efficiency, and quality of operations in various industrial applications.

B-465, Industrial Estate 2nd Gate, Gokul Road, Hubli, 580030 (Karnataka )

Phone: +91-836-2335990

Fax : +91-836-2332297

Cell : +91-93434-03619

Cell 2 :+91-9880-666722

Mr. A.T. Pawar: atpawar@magtoolsindia.com

Mr.Tushar Pawar: tushar@magtoolsindia.com