- B-465, Industrial Estate 2nd Gate, Karnataka, India

- info@magtoolsindia.com

- Mon - Sat 8:30AM - 20.00

In the world of industrial filtration, paper band filters have emerged as a vital component for many applications. These filters offer numerous benefits, ensuring efficient and clean operation across various industries. Let’s delve into the advantages of using paper band filters and understand why they might be the right choice for your filtration needs.

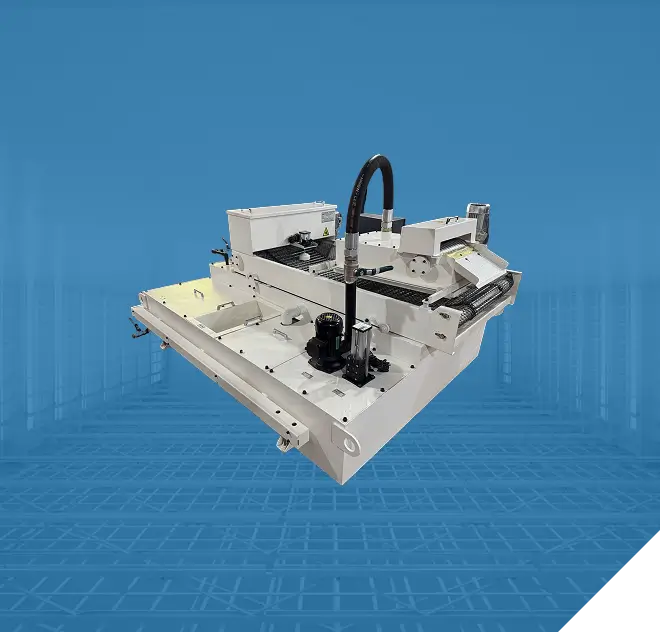

. Its robust design ensures optimal coolant cleanliness, reducing wear and tear on machine components and improving overall productivity.

Ideal for industrial settings, the system is compatible with a wide range of machine tools and coolant types. By incorporating Mag Tools’ Paper Band Coolant Filtration System into your process, you can achieve improved coolant quality, lower operational costs, and extended equipment life.

Optimize your machining environment with Mag Tools’ dependable and efficient Paper Band Coolant Filtration System — the smart choice for maintaining coolant purity and enhancing manufacturing precision.

Environmental Impact: By promoting the recycling of coolant, these filters contribute to environmental sustainability.

Cost Savings: Regular use of paper band coolant filters reduces maintenance costs and extends the life of both the machine and the coolant.

One of the primary advantages of using paper band filters is their high filtration efficiency. They are capable of capturing a wide range of particle sizes, ensuring that even the smallest contaminants are removed from the liquid. This results in a higher quality of the filtered product, which is crucial for industries requiring precise cleanliness standards.

The contaminated coolant is first passed through the magnetic coolant filter which separates almost about 95% of the grinding dust ferrous particles. The liquid is then further passes thru the filter paper media where all the ferrous and non ferrous particles like grinding grit, stainless steel dust, brass and aluminum sludges are filtered by our coolant filtration system. As the porosity of the filter paper media gets clogged up due to the accumulation the dust from the grinding machine

the limit switch triggers the paper band filter geared motor to activate and pull the fresh filter paper media ahead automatically. Now the liquid passes thru the coolant filter paper roll which in turn gives out a signal to the limit switch to shut off the geared motor of paper band coolant filter.

The drive of the drum is achieved by double reduction worm and worm wheel. The worms are made in high carbon steel, hardened and ground which run on sealed ball bearings. The worm wheels are made in high wear resistance materials. An oil indicator is provided to ensure the level of oil in the gear box. This box is designed for continues and trouble free running for years.

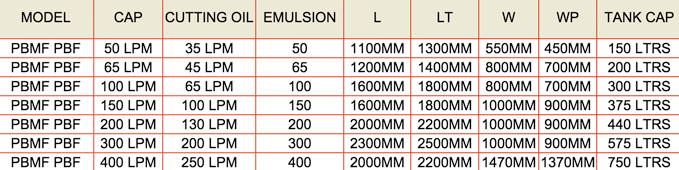

DIMENSIONAL DETAILS OF OUR PAPER BAND COOLANT FILTERS

B-465, Industrial Estate 2nd Gate, Gokul Road, Hubli, 580030 (Karnataka )

Phone: +91-836-2335990

Fax : +91-836-2332297

Cell : +91-93434-03619

Cell 2 :+91-9880-666722

Mr. A.T. Pawar: atpawar@magtoolsindia.com

Mr.Tushar Pawar: tushar@magtoolsindia.com