- B-465, Industrial Estate 2nd Gate, Karnataka, India

- info@magtoolsindia.com

- Mon - Sat 8:30AM - 20.00

Rare earth magnetic filters have become a cornerstone in industrial applications, offering a robust solution for separating ferrous contaminants from various materials. These filters play a crucial role in ensuring product purity and equipment longevity in industries ranging from food processing to chemical manufacturing. In this article, we will explore the benefits and applications of rare earth magnetic filters, and why they are considered superior to traditional industrial filters.

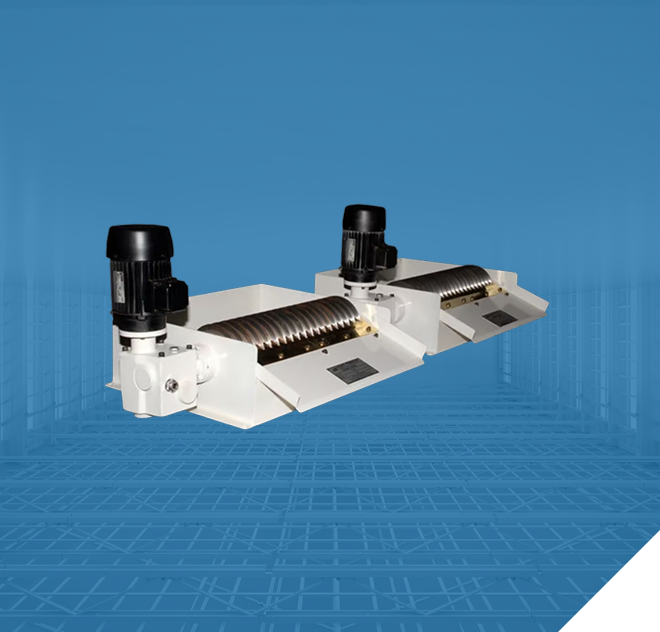

The magnetic drum is made out of powerful rare earth magnets which produce magnetic field 75mm above the drum. Very fine particles will be arrested without a slip. The magnetic material will not loose its strength even after number of years of use.

These filters are available in 100 to 1200 liters per minute filtering capacity. These filters can be coupled with hydrocyclone coolant filters, Paper band filters, Cartridge filters, etc. And are also manufactured as per customers requirement.

The drive of the drum is achived by double reduction worm and worm wheel. The worms are made in high carbon steel, hardned and ground which run on sealed ball bearings. The worm wheels are made in high wear resistance materials. An oil level indicator is provided to ensure the lever of oil in the gear box. The gear box is designed for continuous and trouble free running for years.

The contaminated coolant from the machine is fed into the inlet of the magnetic filter. As it passes thru the gap between the drum and the body, The dust particles are arrested by the drum. A synthetic rubber roller is mounted on springs, squeezes the dust and allows only dry powder, Which is further scraped out from the drum by scraper and is collected in the dust collecting tray. The level of filtration will be almost 95 % for ferrous particles.

These filters can be used with all types of grinding machines such as cylindrical, Centerless, Internal, Surface, Double disc and roll grinding machines. These can also be used for filtered honing oil of honing machines, EDM’s, Washing machines.,

Rare earth magnetic filters are highly effective at removing even the smallest ferrous particles. Their high-intensity magnetic field ensures that contaminants are captured with precision, reducing the risk of product contamination and equipment damage.

Unlike other industrial filters that may wear out over time, rare earth magnetic filters offer exceptional durability. The magnets retain their strength for extended periods, ensuring consistent performance without frequent replacements.

While the initial investment in rare earth magnetic filters may be higher than traditional filters, their longevity and efficiency often lead to cost savings in the long run. Reduced downtime and maintenance costs further enhance their cost-effectiveness.

B-465, Industrial Estate 2nd Gate, Gokul Road, Hubli, 580030 (Karnataka )

Phone: +91-836-2335990

Fax : +91-836-2332297

Cell : +91-93434-03619

Cell 2 :+91-9880-666722

Mr. A.T. Pawar: atpawar@magtoolsindia.com

Mr.Tushar Pawar: tushar@magtoolsindia.com