- B-465, Industrial Estate 2nd Gate, Karnataka, India

- info@magtoolsindia.com

- Mon - Sat 8:30AM - 20.00

Our filtration systems and chip conveyors support a wide range of engineering applications by ensuring clean coolant, smooth operations, and extended machine life. They help maintain precision, efficiency and consistent performance across various machining processes.

We supply high-performance coolant filters and conveyors widely used in automotive component manufacturing. Our systems help reduce downtime, improve machining accuracy and support high-volume production environments.

Our heavy-duty coolant filters and chip handling systems are used in rolling mill operations to manage metal debris, maintain coolant purity and enhance equipment durability. They support smooth, uninterrupted production.

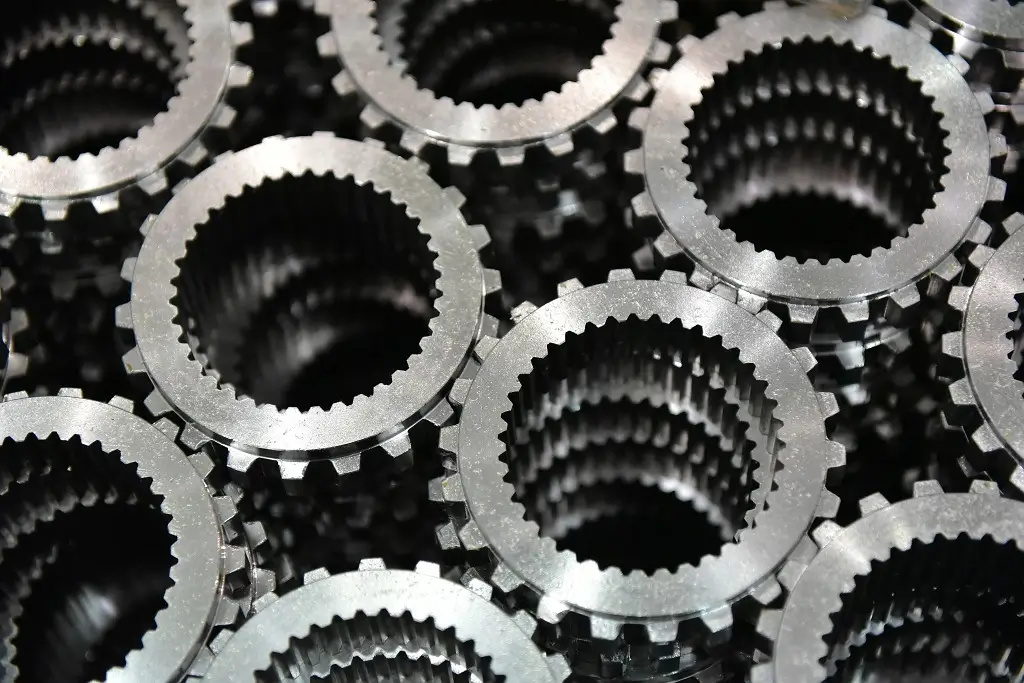

The bearings industry requires exceptional precision, and our filtration solutions ensure clean coolant flow for fine grinding and machining operations. This results in improved surface finish, reduced tool wear and enhanced product quality.

Our filtration equipment is ideal for spindle manufacturing and maintenance processes that demand clean, contamination-free coolant. They ensure smooth machining, higher accuracy and longer machine and spindle life.

We provide reliable filtration and conveyor solutions used in the production and maintenance of textile machinery components. These systems help maintain operational cleanliness, reduce waste and support continuous industrial performance.

In wire drawing processes, controlling impurities is crucial. Our filtration systems help maintain clean coolant, reduce friction and improve the overall quality and consistency of drawn wires. This results in better productivity and reduced maintenance downtime.

With decades of experience, we deliver reliable filtration and conveyor solutions across engineering, automobile, textile, bearings, spindle, rolling mill, and wire drawing industries.

Every product goes through strict quality checks to ensure durability, accuracy, and consistent performance.

Along with a wide range of standard models, we design and manufacture special or large systems tailored to your specific application.

We use modern manufacturing techniques and high-efficiency components to ensure superior filtration, smooth material handling, and long-term operational stability.

Our skilled engineering team provides full technical assistance—from selection to installation—to ensure seamless integration with your machinery.

We prioritize your requirements, delivering timely service, dependable products, and long-lasting partnerships.

Our coolant management products help maintain fluid clarity, temperature, and purity, ensuring prolonged coolant life and superior machining output. Systems include magnetic filters, coolant chillers, paper band filters, hydrocyclone separators, and centralized filtration setups.

We supply high-performance Filters and Chip Conveyors suitable for both indigenous and imported machines. Many leading machine tool builders use our systems as original fitments, showcasing our strong reliability and engineering capability.

Our wide range of standard models ensures quick selection, while special and large-scale systems can be custom-designed as per application needs.

Mag Tools provides automation-ready filtration and conveying solutions designed to integrate seamlessly with CNC machines, robotic cells, and automated production lines. Our systems help manufacturers achieve consistent output and process reliability.